Check stock, it’s not just about counting beans, it’s about keeping your business from going belly up. Think of it like a well-oiled machine – if you don’t have the right parts in the right place at the right time, everything grinds to a halt. From the bustling aisles of a Walmart to the intricate production lines of a car factory, accurate stock management is the secret sauce to success.

Imagine a world where your favorite video game console is always out of stock, or your go-to coffee shop runs out of beans before lunchtime. That’s the nightmare scenario of insufficient stock, and it’s a reality for businesses that don’t have a solid plan in place. On the flip side, having too much stock can be just as bad – it ties up your cash flow and eats away at your profits. So, how do you strike the perfect balance? That’s where check stock comes in.

Understanding Stock Checking

You know how they say, “Inventory is king”? Well, it’s true! Knowing how much of what you have on hand is crucial for any business, especially in the fast-paced world we live in. Imagine a world where you can’t get your favorite sneakers or the latest iPhone because the store is out of stock. Not cool, right? That’s where stock checking comes in – it’s like the superhero of the supply chain, ensuring that you don’t end up with empty shelves or a warehouse full of stuff no one wants.

The Importance of Stock Checking

Stock checking is more than just counting boxes; it’s about understanding the flow of goods, from the moment they arrive until they reach the customer. This is super important because it helps businesses make smarter decisions about what to order, how much to order, and when to order it. Think of it like a game of Tetris – you need to fit all the pieces together perfectly to avoid a pileup.

- Preventing Stockouts: Imagine you’re running a clothing store and your best-selling jeans are out of stock. You’ve just lost a sale, and potentially a customer, because you didn’t have enough product on hand. Stock checking helps you avoid this by keeping a close eye on your inventory levels and ordering more before you run out.

- Reducing Excess Inventory: On the flip side, having too much stock can be just as bad as not having enough. Imagine you’re a toy store and you’ve ordered a ton of a specific toy, only to find out that it’s not as popular as you thought. Now you’re stuck with a bunch of unsold toys, taking up space and costing you money. Stock checking helps you avoid this by analyzing sales data and ordering just the right amount.

- Improving Customer Satisfaction: When customers can find what they want, when they want it, they’re happy. That’s why accurate stock checking is crucial for maintaining customer satisfaction. If you can consistently deliver on your promises, you’ll build a loyal customer base.

Consequences of Insufficient or Excessive Stock

So, we’ve talked about the benefits of accurate stock checking, but what happens when things go wrong? Well, it’s like a game of dominoes – one mistake can set off a chain reaction.

- Lost Sales: If you run out of stock, you lose the opportunity to sell products. This can be especially damaging during peak seasons or when you’re trying to capitalize on a trend.

- Damaged Reputation: If customers can’t find what they’re looking for, they’re likely to get frustrated and go elsewhere. This can damage your reputation and make it harder to attract new customers.

- Increased Costs: Excess inventory ties up cash flow and can lead to storage costs. It can also result in waste if products expire or become obsolete.

Businesses That Rely Heavily on Accurate Stock Management

Here are some examples of businesses that rely heavily on accurate stock management:

- Retail Stores: Retail stores, from clothing boutiques to supermarkets, need to keep track of their inventory to ensure they have enough products to meet customer demand.

- E-commerce Businesses: E-commerce businesses rely on accurate stock checking to fulfill orders quickly and efficiently. They need to be able to track their inventory levels in real-time to avoid delays and customer dissatisfaction.

- Manufacturing Companies: Manufacturing companies need to keep track of their raw materials, components, and finished goods to ensure they can produce products on time and within budget.

Methods for Checking Stock

Stock checking is a crucial aspect of inventory management, ensuring businesses have enough products to meet customer demand without incurring unnecessary costs. Choosing the right stock checking method depends on factors like business size, budget, and the complexity of your inventory.

Manual Counting

Manual counting is the most basic method, involving physically counting each item in your inventory. It’s simple and straightforward, but it can be time-consuming, prone to errors, and labor-intensive, especially for large inventories.

Barcode Scanning

Barcode scanning uses scanners to read barcodes attached to each item. This method is faster and more accurate than manual counting, reducing the risk of human error. It’s widely used in retail, warehouses, and manufacturing facilities.

- Advantages: Faster and more accurate than manual counting, reduces human error, and integrates with inventory management systems.

- Disadvantages: Requires initial investment in scanners and barcodes, may not be suitable for small businesses with limited inventory.

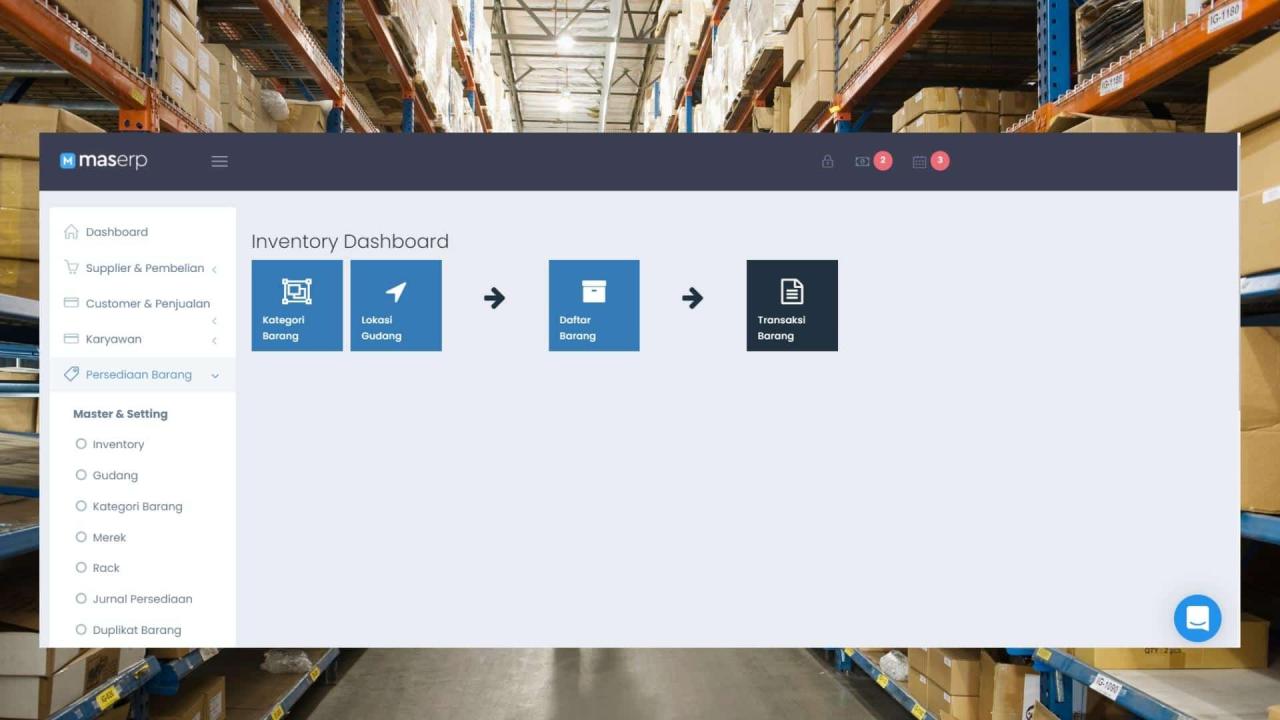

Automated Inventory Systems

Automated inventory systems use sensors, RFID tags, and software to track inventory levels in real-time. These systems provide accurate data on stock levels, allowing businesses to optimize inventory management, minimize stockouts, and reduce costs.

- Advantages: Real-time inventory visibility, improved accuracy, reduced labor costs, and better inventory control.

- Disadvantages: Higher initial investment, requires technical expertise to set up and maintain, and may not be suitable for all businesses.

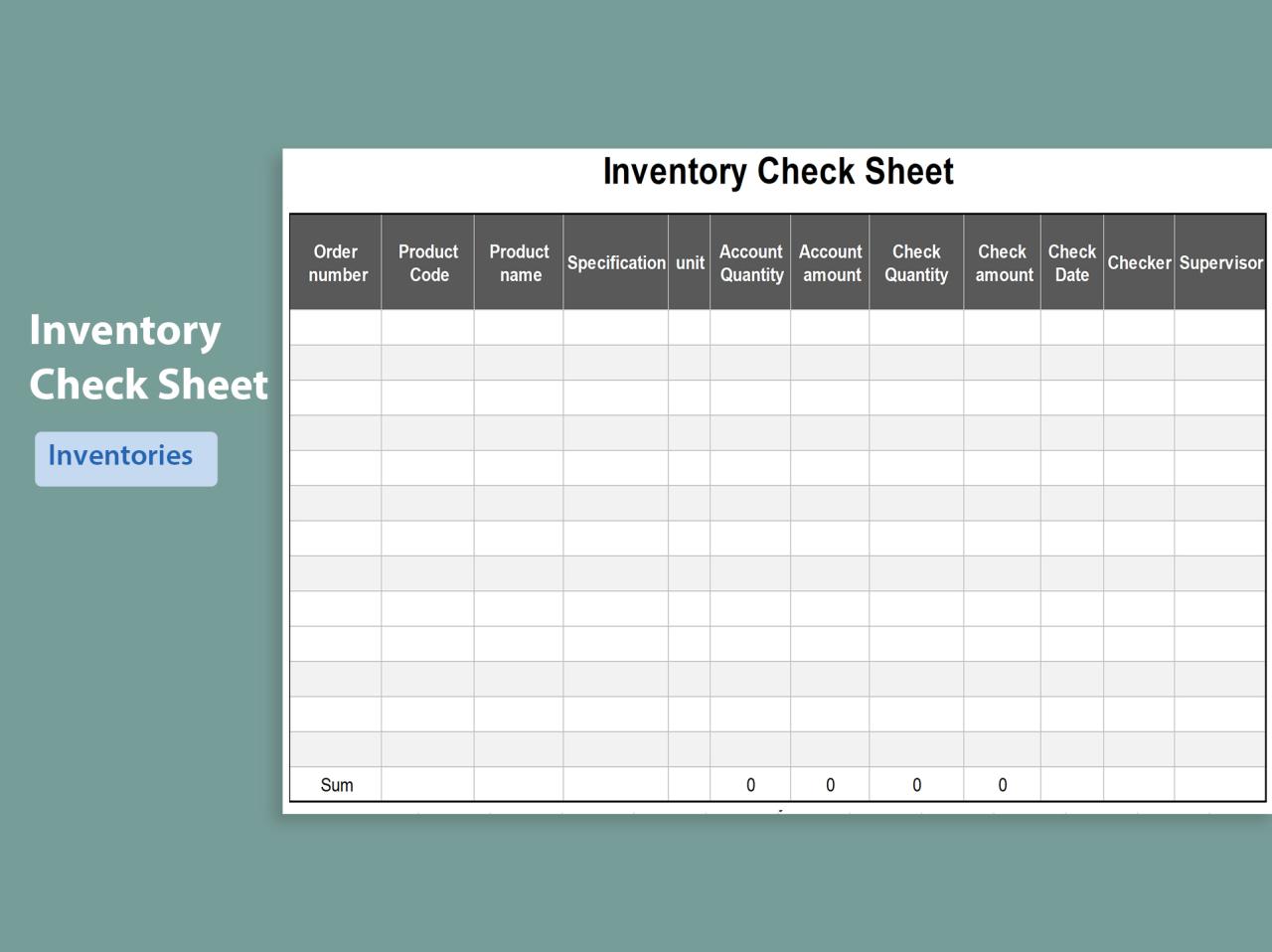

Comparison of Stock Checking Methods

| Method | Features | Cost | Suitability |

|---|---|---|---|

| Manual Counting | Simple, low-cost, requires no technology | Low | Small businesses with limited inventory |

| Barcode Scanning | Faster, more accurate, integrates with inventory systems | Moderate | Retail stores, warehouses, and manufacturing facilities |

| Automated Inventory Systems | Real-time visibility, high accuracy, advanced features | High | Large businesses with complex inventory and high volume |

Stock Checking Tools and Technologies

Imagine trying to keep track of your inventory without any help. You’d be running around like a chicken with its head cut off, trying to remember what you have, where it is, and how much you need to order. Luckily, we live in a world where technology can make our lives easier. That’s where stock checking tools and technologies come in.

Software Applications

Software applications are the unsung heroes of stock checking. They make the whole process smoother, faster, and less prone to human error.

- Inventory Management Systems (IMS): These are like the brains of your stock checking operation. They handle everything from tracking your inventory levels to managing your orders and even forecasting your future needs. Think of them as your personal inventory assistants. Popular IMS options include:

- NetSuite: A comprehensive suite of business applications, including inventory management. NetSuite offers features like real-time inventory tracking, purchase order management, and automated reporting.

- SAP Business One: A robust ERP system with a strong focus on inventory management. SAP Business One provides detailed inventory tracking, warehouse management, and advanced analytics.

- Zoho Inventory: A cloud-based inventory management system designed for small and medium businesses. Zoho Inventory offers features like multi-warehouse management, purchase order processing, and order fulfillment.

- Point of Sale (POS) Systems: These are the front-line soldiers in your stock checking army. They keep track of your sales and automatically update your inventory levels. Popular POS options include:

- Square: A popular POS system known for its user-friendly interface and mobile compatibility. Square offers features like real-time inventory tracking, sales reporting, and customer management.

- Shopify: A leading e-commerce platform with a built-in POS system. Shopify offers features like online and in-store sales management, inventory syncing, and order fulfillment.

- Lightspeed: A cloud-based POS system designed for retail and hospitality businesses. Lightspeed offers features like inventory management, customer loyalty programs, and reporting.

- Barcode Scanners: These are the workhorses of stock checking. They allow you to quickly and accurately scan barcodes on your inventory, which then feeds information back to your IMS.

Hardware Devices

Hardware devices provide the physical tools that help you keep track of your inventory. They work in tandem with software applications to create a seamless stock checking system.

- Barcode Printers: These printers create the barcodes that you scan using barcode scanners. They’re essential for labeling your inventory accurately and efficiently.

- RFID Readers: RFID (Radio Frequency Identification) readers are used to track inventory using RFID tags. These tags contain unique identifiers that can be read from a distance, making them ideal for tracking large quantities of items.

- Mobile Computers: These devices, often equipped with barcode scanners and RFID readers, allow you to check stock levels and manage inventory on the go.

Essential Tools and Technologies

To make your stock checking process as efficient as possible, consider these essential tools and technologies:

- Inventory Management Software: As mentioned earlier, an IMS is the backbone of any effective stock checking system.

- Barcode Scanners: These are essential for quickly and accurately scanning barcodes on your inventory.

- RFID Technology: RFID technology is particularly useful for tracking large quantities of inventory, especially in warehouses and distribution centers.

- Cloud-Based Solutions: Cloud-based inventory management solutions offer flexibility and scalability, allowing you to access your inventory data from anywhere with an internet connection.

- Real-Time Data: Real-time inventory data provides you with up-to-the-minute information on your stock levels, helping you make informed decisions about ordering, pricing, and promotions.

- Data Analytics: Using data analytics tools, you can gain valuable insights into your inventory trends, identify areas for improvement, and optimize your stock checking processes.

Best Practices for Stock Checking

You’ve got your stock-checking system in place, but are you maximizing its effectiveness? It’s time to level up your stock-checking game and ensure you’re running a tight ship, just like your favorite NBA team. Here are some best practices to help you nail those stock checks like a pro.

Importance of Consistent Stock Checking Schedules, Check stock

A consistent stock-checking schedule is like a well-rehearsed dance routine – every move is planned and executed with precision. It helps you stay on top of your inventory levels, avoid stockouts, and prevent unnecessary overstocking. Think of it like a well-oiled machine, running smoothly and efficiently.

- Regular Stock Checks: Establish a regular schedule for stock checks, whether it’s daily, weekly, or monthly. This frequency will depend on your inventory turnover rate and the type of products you sell. Just like checking your social media notifications, it’s best to do it frequently to stay on top of things.

- Cycle Counting: Cycle counting is a continuous process of verifying stock levels in specific areas of your warehouse. It’s like taking a snapshot of your inventory at different times to ensure accuracy. Think of it like a quick “check-in” with your inventory to make sure everything’s in order.

- Physical Inventory Counts: Periodically conduct a full physical inventory count, which involves manually checking every item in your warehouse. This is like a “deep clean” for your inventory, ensuring that everything is accounted for. It might be a bit more time-consuming, but it’s worth it for a thorough and accurate inventory assessment.

Optimizing Stock Checking Procedures

Optimizing your stock-checking procedures is like streamlining your workflow. It’s about making things easier, faster, and more efficient. Think of it like using a shortcut to get to your favorite app on your phone – it saves time and effort.

- Clearly Defined Stock Checking Areas: Divide your warehouse into distinct stock-checking zones. This makes it easier to track and manage inventory and prevents you from getting lost in the sea of products. It’s like having a map to navigate your warehouse.

- Streamlined Stock Checking Processes: Implement standardized procedures for stock checking. This ensures consistency and minimizes errors. Think of it like a recipe for success – following the steps will ensure you get the desired results.

- Technology Integration: Utilize barcode scanners, handheld computers, and other stock-checking tools. These technologies can automate the process, reduce manual errors, and improve efficiency. It’s like having a personal assistant to help you with your stock checks.

- Training and Documentation: Train your team on proper stock-checking procedures and provide clear documentation. This ensures everyone is on the same page and minimizes errors. It’s like having a team playbook to guide your stock-checking efforts.

Stock Checking in Different Contexts

Stock checking is not a one-size-fits-all process. Different industries, business models, and even specific products have unique needs and challenges when it comes to managing inventory. Understanding these nuances is crucial for optimizing stock checking strategies and ensuring smooth operations.

Stock Checking in Retail

Retailers face the challenge of balancing supply and demand for a vast array of products. They need to ensure enough stock is available to meet customer needs without overstocking and incurring storage costs.

- Fast-moving consumer goods (FMCG): Retailers dealing with FMCG like groceries, toiletries, and beverages need frequent stock checks to avoid stockouts and meet customer demand. They use tools like point-of-sale (POS) systems and inventory management software to track sales and replenish stock in real-time.

- Seasonal products: Retailers selling seasonal items like clothing, toys, or holiday decorations need to anticipate demand fluctuations and adjust stock levels accordingly. They may use historical data and market trends to forecast demand and optimize stock ordering.

- High-value items: For expensive items like electronics or jewelry, retailers need to implement stringent stock control measures to prevent theft and loss. They may use security tags, CCTV cameras, and specialized inventory management systems to track high-value products.

Stock Checking in Manufacturing

Manufacturers have to manage raw materials, work-in-progress inventory, and finished goods. They need to ensure that materials are available for production, work-in-progress is moving efficiently, and finished goods are ready for shipment.

- Just-in-time (JIT) manufacturing: Manufacturers using JIT rely on precise stock checking to ensure materials arrive just before they are needed for production. This minimizes storage costs and reduces waste but requires careful planning and coordination.

- Material requirements planning (MRP): MRP systems help manufacturers plan and manage materials based on production schedules and demand forecasts. They use stock checking data to determine material needs, optimize production runs, and minimize waste.

- Quality control: Manufacturers need to check stock for quality defects during production and before shipment. This ensures that only high-quality products are delivered to customers, minimizing returns and reputational damage.

Stock Checking in Logistics

Logistics companies are responsible for the movement and storage of goods. They need to track inventory levels, optimize warehouse space, and ensure timely delivery to customers.

- Warehouse management: Logistics companies use stock checking to optimize warehouse space utilization and manage inventory flow. They employ tools like warehouse management systems (WMS) and barcode scanners to track goods and ensure efficient picking and packing processes.

- Transportation management: Logistics companies need to track inventory in transit to ensure timely delivery and minimize delays. They use GPS tracking systems, real-time inventory management software, and communication tools to monitor shipments and ensure smooth transportation.

- Inventory visibility: Logistics companies need to provide their clients with real-time inventory visibility. This allows customers to track their orders, manage stock levels, and optimize their own supply chains.

Stock Checking in Online Businesses

Online businesses face unique challenges when it comes to stock checking. They need to manage inventory across multiple locations, handle online orders, and ensure timely delivery.

- Real-time inventory updates: Online businesses need to update their inventory levels in real-time to avoid overselling and ensure customer satisfaction. They use online platforms and software to manage inventory and provide accurate product availability information.

- Order fulfillment: Online businesses need to manage order fulfillment efficiently to meet customer expectations. They use stock checking data to track orders, manage shipping, and ensure timely delivery.

- Dropshipping: Businesses using dropshipping models rely heavily on accurate stock checking from their suppliers. They need to ensure that their suppliers have sufficient stock to fulfill orders and meet delivery deadlines.

Stock Checking in Offline Businesses

Offline businesses face challenges like limited shelf space, potential for theft, and the need to physically count inventory.

- Point-of-sale (POS) systems: Offline businesses use POS systems to track sales and update inventory levels. They can use barcode scanners to quickly check stock levels and ensure accuracy.

- Physical inventory counts: Offline businesses often need to perform physical inventory counts to verify stock levels and identify discrepancies. This can be a time-consuming process but is essential for maintaining accurate stock records.

- Security measures: Offline businesses need to implement security measures to prevent theft and loss of inventory. This may include using security cameras, alarms, and staff training to deter theft and ensure stock accuracy.

The Future of Stock Checking

The future of stock checking is as bright as a warehouse full of neon lights! Get ready for a revolution in how we manage inventory, thanks to the power of automation, artificial intelligence, and data analytics. These technologies are going to take stock checking from a manual chore to a super-powered, real-time operation.

Automation and Robotics

Automation and robotics are going to be the next big thing in stock checking. Imagine robots zipping around your warehouse, scanning barcodes, and updating inventory levels in real-time. No more manual counting or tedious data entry! This will not only save time and money but also reduce errors and improve accuracy.

Artificial Intelligence (AI)

AI is going to be the brains behind the operation, helping us make smarter decisions about stock management. AI-powered systems can analyze vast amounts of data to predict demand, identify trends, and optimize inventory levels. They can even learn from past experiences to improve their predictions over time.

Data Analytics

Data analytics will be the key to unlocking the full potential of stock checking. By analyzing data from various sources, such as sales records, customer behavior, and supplier information, we can gain valuable insights into stock performance. This data can help us identify bottlenecks, optimize supply chains, and make informed decisions about inventory management.

Timeline of Key Milestones

- 2020s: The rise of cloud-based stock checking solutions and the integration of mobile devices for real-time inventory updates.

- Mid-2020s: The emergence of AI-powered stock management systems that can predict demand, optimize inventory levels, and automate stock checking processes.

- Late 2020s: The widespread adoption of robotics and automation in warehouses, leading to increased efficiency and reduced labor costs.

- 2030s: The development of advanced AI systems that can learn and adapt to changing market conditions, providing real-time insights and recommendations for stock management.

Outcome Summary: Check Stock

From manual counting to cutting-edge AI, the world of stock checking is constantly evolving. Whether you’re a small business owner or a corporate giant, understanding the importance of accurate stock management is crucial. It’s the key to keeping your customers happy, your profits flowing, and your business thriving in a competitive world. So, ditch the guesswork and embrace the power of check stock – it’s the secret weapon your business needs to level up!

Frequently Asked Questions

What happens if I don’t check my stock?

You risk running out of products, losing sales, and disappointing customers. It can also lead to production delays and inefficiencies.

How often should I check my stock?

The frequency depends on your business and industry. For fast-moving items, daily checks might be necessary, while slower-moving items can be checked weekly or monthly.

What are some common stock checking mistakes?

Common mistakes include inaccurate counting, outdated inventory records, and failing to account for damaged or expired goods.